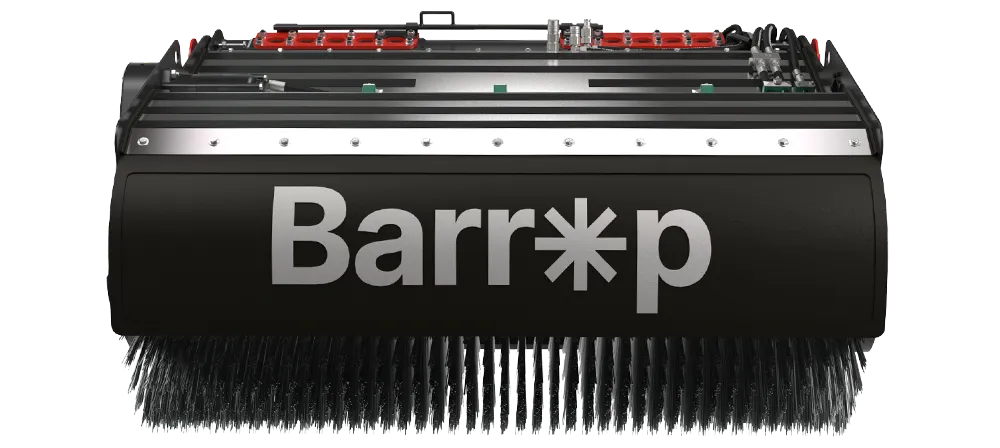

Steel brush with more than

28,000 friction points

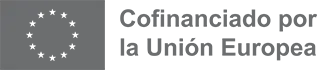

The Barrop was born with the commitment to create a unique sweeping implementin the public works market, offering unprecedented production capacity and durability.

Each sweeper is handmade, numbered, and registered as one-of-a-kind in the market.

Brush Structure

Durability

Our brush is designed to havean exceptionally long lifespan, 10 times greater than any other sweeper on the market.

Thanks to its innovative system, it can reach up to 1.000 hours of operation on highly abrasive surfaces. On less aggressive terrains, its lifespan increaseseven further.

Sweepers

with plastic

brushes.

More than

1.000 hours

on abrasive

materials.

Length

The Barrop brush features a 70 cm ring diameter and 24 cm long bristles, allowing it to cover a larger sweeping area with each pass.

This optimized length not only improves cleaning efficiency but also extends the brush’s lifespan, reducing the need for frequent replacements and ensuring consistent performance even under demanding working conditions.

Easy Assembly

The brush structure allows for installation in minutes, guaranteeing speed and efficiency in the process.

Its design enables assembly without the need for specialized tools, minimizing downtime and ensuring the sweeper can be operational from the very first moment.

Sweeps Hot Materials

Thanks to its steel brush, the Barrop can operate on hot materials without compromising its performance.

Unlike polypropylene, this material allows it to sweep asphalt residues and other high-temperature materials without deformation or damage.

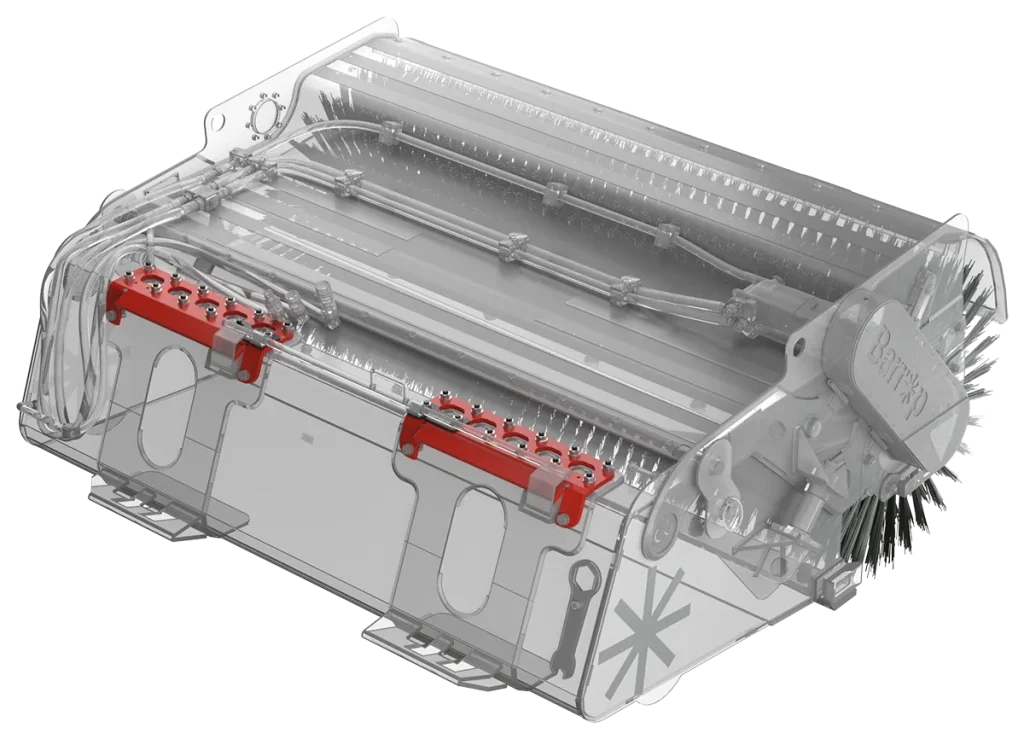

Sweeper Structure

Removable Side

The detachable design allows the brush to be replaced quickly, without the need for heavy machinery or disassembling the entire axle.

This innovative structure facilitates maintenance directly on-site, reducing wait times and avoiding unnecessary trips to workshops. Operators can replace the brush in a short time, maintaining productivity.

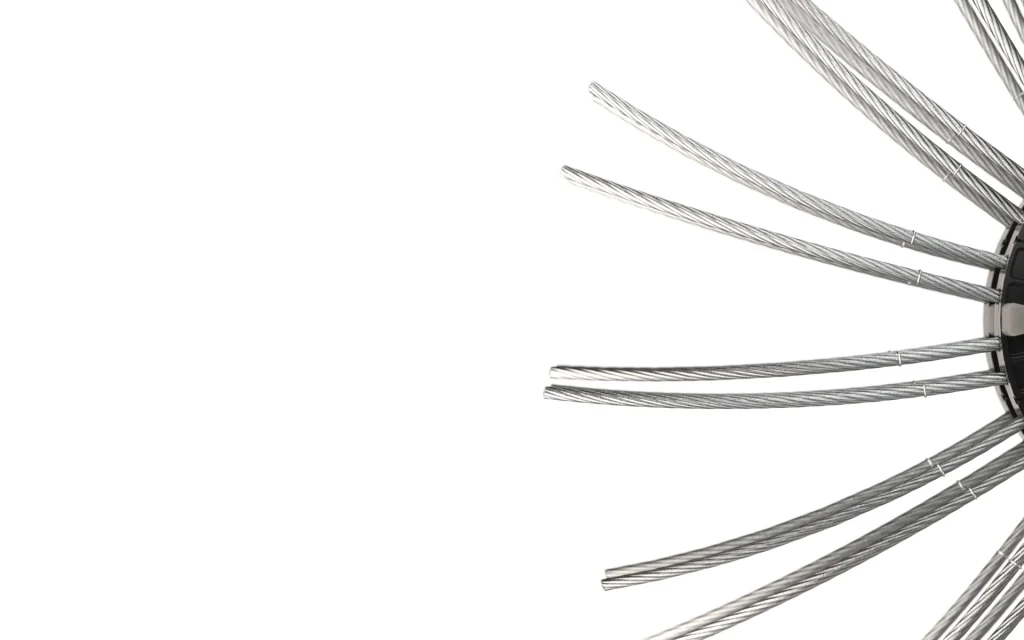

Bearing Support

The patented bearing support is designed in a “sandwich” system, ensuring stable fixation and extending the bearing’s lifespan, even under high-load conditions.

If the bearing breaks, it can continue working without stopping during the workday.

Reinforced Sides

The sweeper’s sides are made of

high-yield steel plates, providing

greater resistance to impacts and deformations during

intensive tasks.

Anti-Wear

Lasts longer.

Much longer.

Friction Without Wear

All key Barrop components are made with

Hardox 500, the material that redefines resistance and

multiplies durability.

35 mm Thick Blade

Its impressive thickness, supported by a maximum-security anchor,

ensures complete wear without losing firmness or resistance.

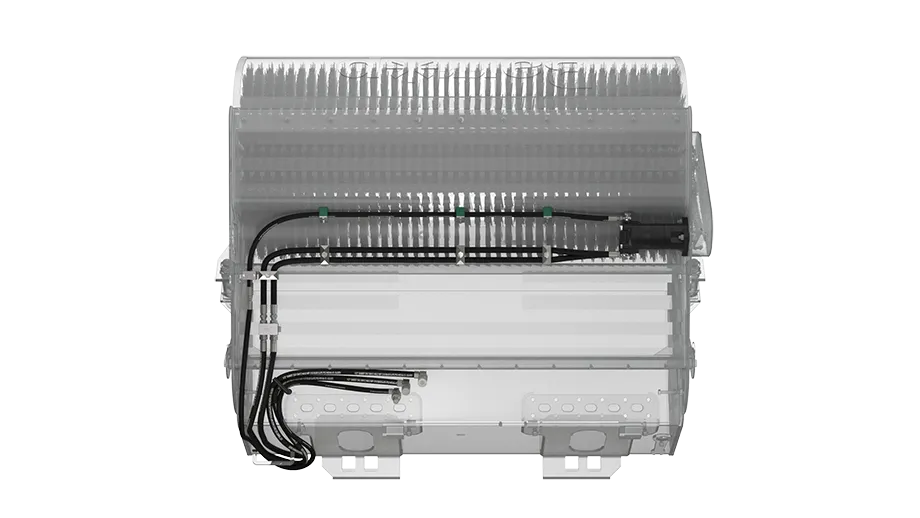

Hydraulic System

Advanced hydraulic power,

accessible to everyone

The hydraulic system features an external motor that provides limitless accessibility:

Forget complications. With the motor strategically placed on the outside, maintenance has never been so easy. Access key components in minutes and keep productivity running.

Hydraulic System

Eaton OMP 200 motor with bearing system for greater durability.

Models 2800 and 3000 are equipped with two motors.

Hoses and Connections

The hydraulic system consists of two connections—one for input and one for return—and a third relief hose.

This way, we protect the motor from potential hydraulic pressure spikes.

The hose connections are quick-release; all spare parts can be found in our spare parts list.

Chain Transmission

System consisting of an 11-tooth motor sprocket,

a 21-tooth brush shaft sprocket,

and an ASA 60 chain.

It offers easy access for maintenance.

+

Collector Structure

Movable

We understand the challenges sweepers face with New Jersey barriers, curbs, milling machine steps, and more.

That’s why we’ve developed a way to shift the implement to the left, preventing potential tire rubbing and improving sweeping quality.

Removable Bob-Tach Hitch

The Barrop’s removable Bob-Tach hitch system allows for a quick and secure connection to the driving machine.

No limits.

No corrosion.

We manufacture sweepers entirely from stainless steel, designed for companies working with highly corrosive materials like fertilizers and other aggressive compounds.

Thanks to stainless steel’s resistance, our sweepers guarantee greater durability and lower maintenance in demanding environments. Additionally, we adapt to each client’s specific needs, offering customized solutions that optimize performance and extend equipment lifespan.